Exploration & Production

Product Range Main Features

Standards & Specifications

Best Cases/ References

We're supporting our customers in their Exploration & Production fields, with an extended product range of Cable Solutions, developed specifically for the Exploration & Production sector.

The Prysmian Group range of Cable Solutions for upstream applications delivers innovative solutions for drilling, completion and surface production applications.

● Enhanced fire resistance

● Enhanced resistance to oil, hydrocarbons and chemical attacks

● Enhanced flexibility and compact design for lower TCO

● All major international and local standards (IEC, NEK, IEEE, UL, CSA, BS, etc.)

● Custom requirements

High Voltage & Submarine Cables

|

|

Conductor Materials: |

Copper or aluminium conductors longitudinally water blocked |

|---|---|

|

Conductor Screen: |

Extruded semi conductive compound |

|

Insulation: |

EPR |

|

Insulation Screen: |

Extruded semi conductive compound |

|

Screen: |

Individual Cu-tape screen on each phase - static applications |

|

Fibre Optic Unit: |

Up to 3 FO units with metal tube |

|

Lay up: |

Three power cores laid up with fillers |

|

Armour Bedding: | Polypropylene yarns |

|

Armouring: | One layer of galvanized steel wires, flushed with bitumen |

|

Outer Protection: | Polypropylene yarns - static applications PE - dynamic applications |

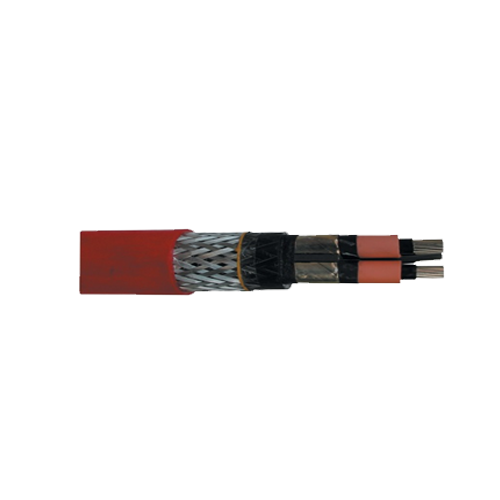

Medium Voltage Cables

|

|

Conductor Materials: | Copper (plain or tinned) |

|---|---|

|

Insulation: | EPR/XLPO/XLPE |

|

Screen: | Tinned copper wire braid |

|

Fire Barrier | Tapes |

|

Inner Sheath: | EVA/Neoprene/LS0H |

|

Armouring: | Bronze braid/Steel braid/Copper braid |

|

Outer Sheath: | Neoprene/EVA/LS0H |

Other Features | Mud resistant |

|

|

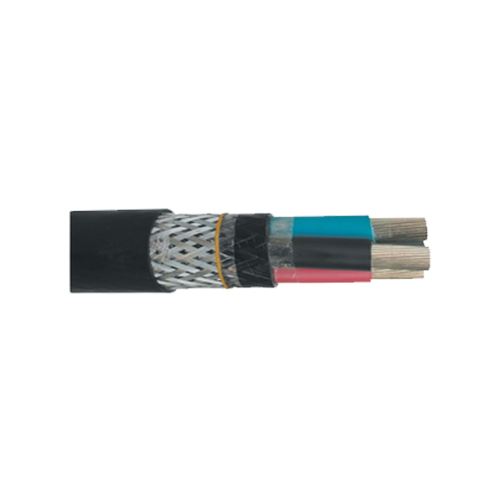

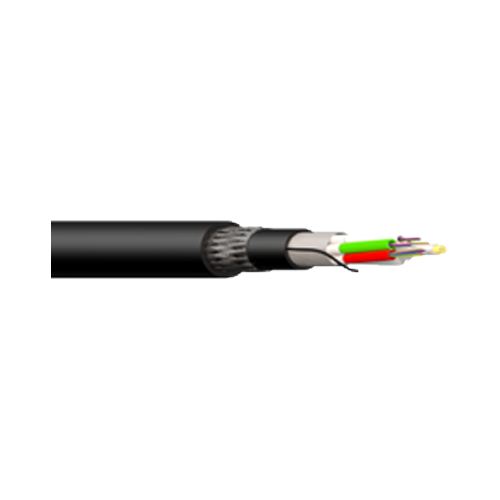

Low Voltage & Control Cables

|

|

Conductor Materials: |

Copper (plain or tinned) |

|---|---|

|

Insulation: |

EPR/XLPO/XLPE |

|

Screen: |

Tinned copper wire braid 100% coverage |

|

Fire Barrier (where applicable): |

Tapes |

|

Inner Sheath: |

EVA/Neoprene/LS0H |

|

Armouring: |

Bronze braid/Steel braid/Copper braid |

|

Outer Sheath: |

Neoprene/EVA/LS0H |

Other Features (where applicable): |

Mud resistant |

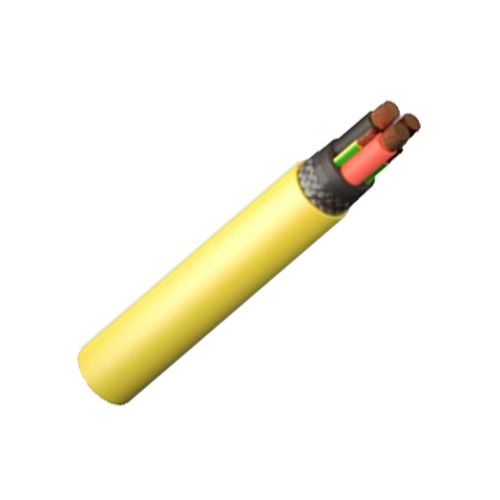

VFD Cables

|

|

Conductor Materials: |

Copper (plain or tinned) |

|---|---|

|

Insulation: |

EPR/XLPO/XLPE |

|

Screen: |

Tinned copper wire braid |

|

Fire Barrier (where applicable): |

Tapes |

|

Inner Sheath: |

EVA/Neoprene/LS0H |

|

Armouring: |

Bronze braid/Steel braid/Copper braid |

|

Outer Sheath: |

Neoprene/EVA/LS0H |

Other Features (where applicable): |

Mud resistant |

|

|

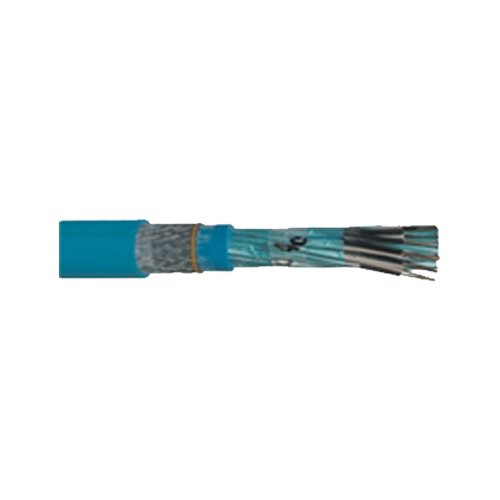

Instrumentation Cables

|

|

Conductor Materials: |

Copper (plain or tinned) |

|---|---|

|

Insulation: |

EPR/XLPO/XLPE |

|

Screen: |

Tape-Cu/PET or |

|

Fire Barrier |

Tapes |

|

Inner Sheath: |

EVA/Neoprene/LS0H |

|

Armouring: |

Bronze braid/Steel braid/Copper braid |

|

Outer Sheath: |

Neoprene/EVA/LS0H |

Other Features |

Mud resistant |

|

|

Fibre Optic Cables

|

Design Options and Features

AICI |

QFCI |

S611T |

S670T |

|

|---|---|---|---|---|

Design: |

Loose Tube |

Loose Tube |

Tight Buffer |

Tight Buffer |

Reinforced Fibre: |

N/A |

N/A |

Single+Overall |

Single+Overall |

Armoured/Unarmoured: |

GSWB |

GSWB |

Unarmoured |

BWB |

LSZH: |

Y |

Y |

Y |

Y |

Fire Resistant: |

N |

Y |

N |

N |

Oil Resistant/MUD: |

Oil Resistant/MUD |

Y/Optional |

Y/N |

Y/N |

Service Loops and Bridles

Hose Style Loops

|

Hose Style Loops with

|

Bostdrive™ Cable Service Loops

|

|

ESP Cables

|

Conductors: |

Solid, or stranded sealed conductors |

|---|---|

|

Insulation: | Polypropylene or EPDM insulation |

|

Barriers: | Fatigue and corrosion resistant lead sheath |

|

Tape & Braid: | A variety of materials to suit application |

|

Jackets: |

EPDM/Nitrile Rubber |

|

Armour: | Galvanized steel, stainless steel or Monel tapes |

|

Optional Capillary tubing: | Stainless steel tubing incorporated in round or flat cable designs |

Best Cases/References

|