X

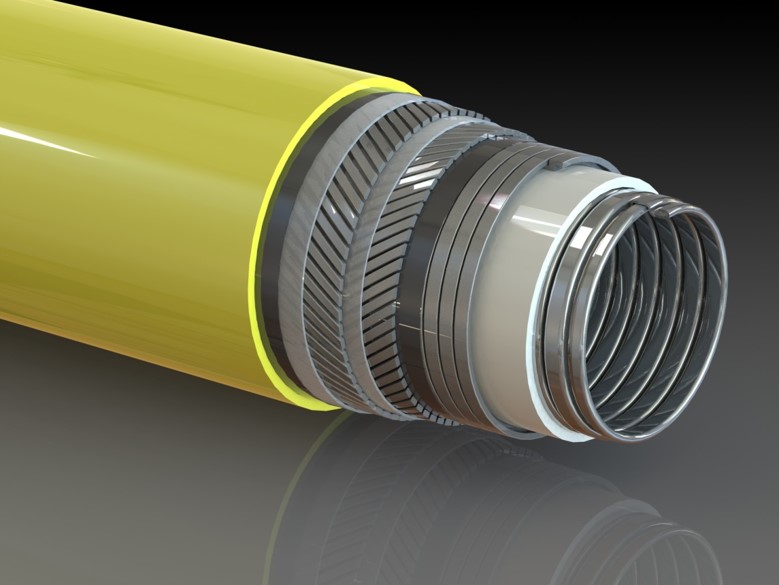

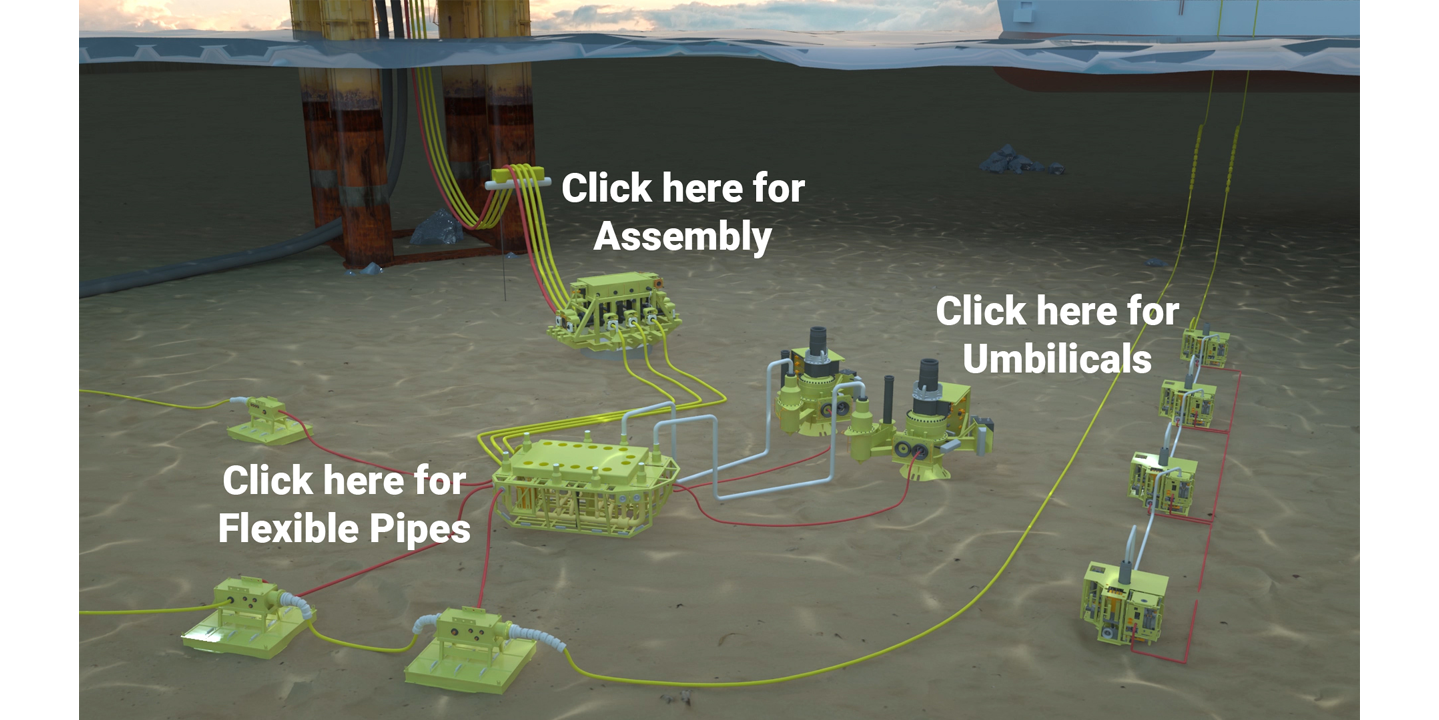

Flexible Pipes

|

|

|

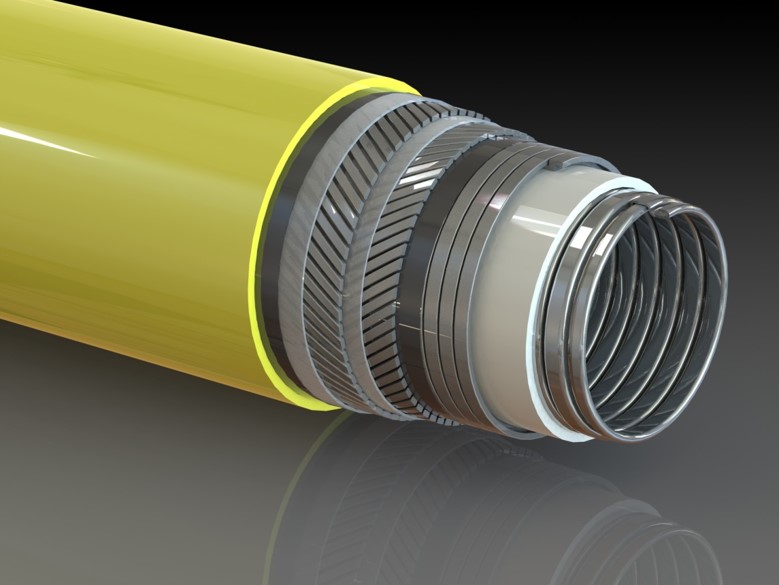

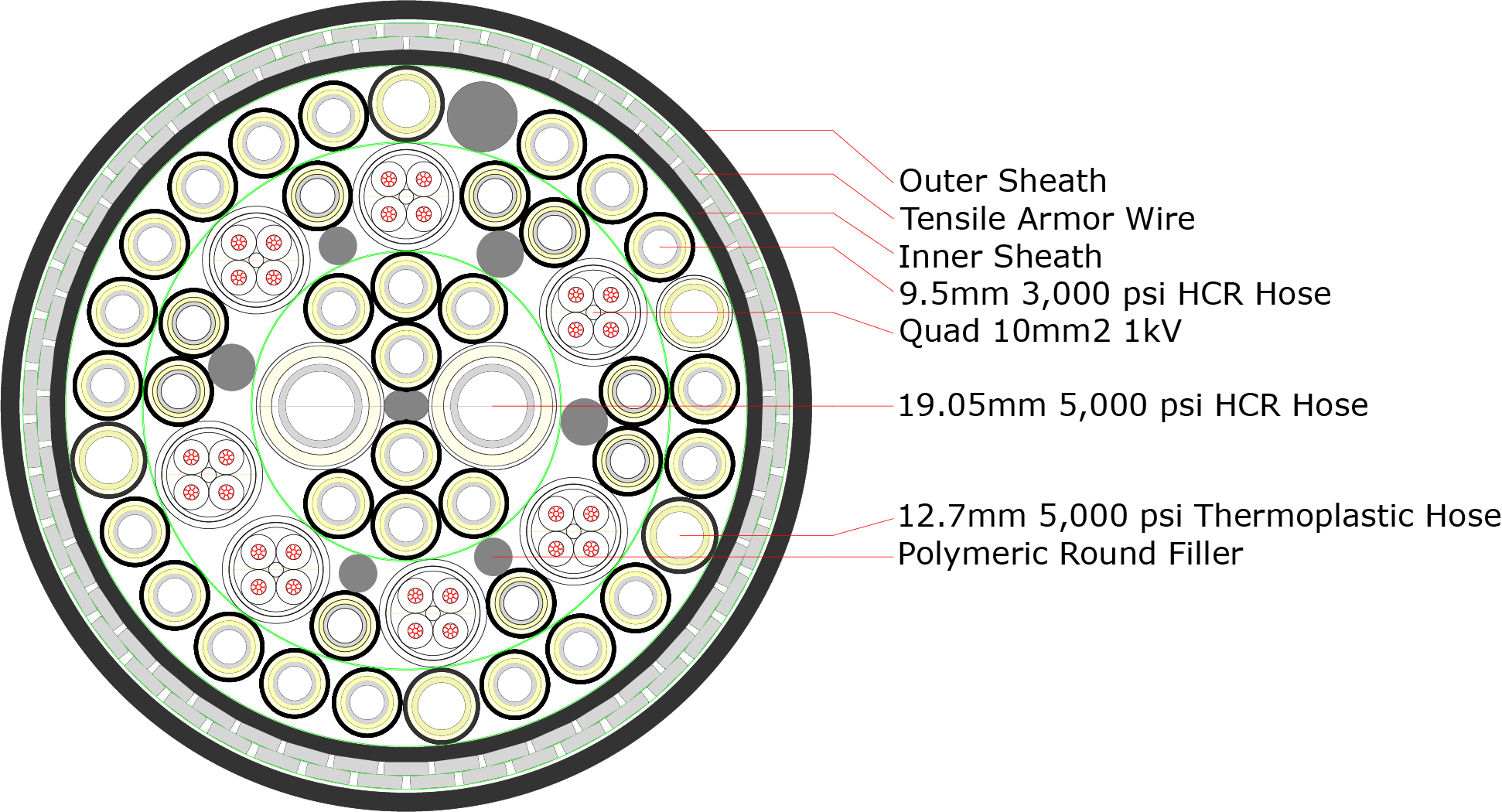

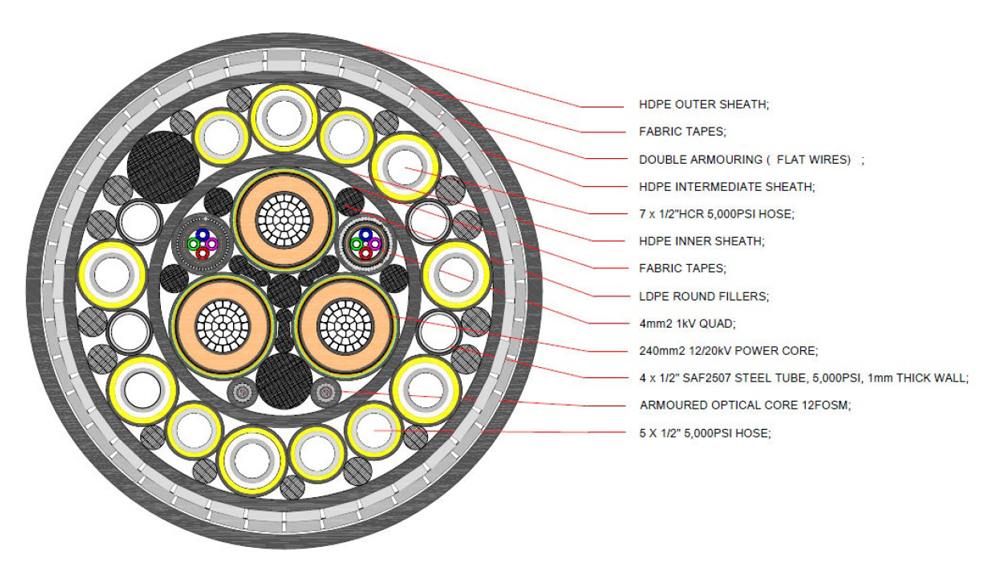

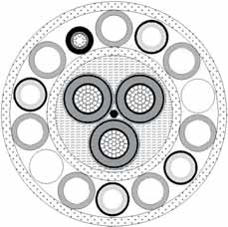

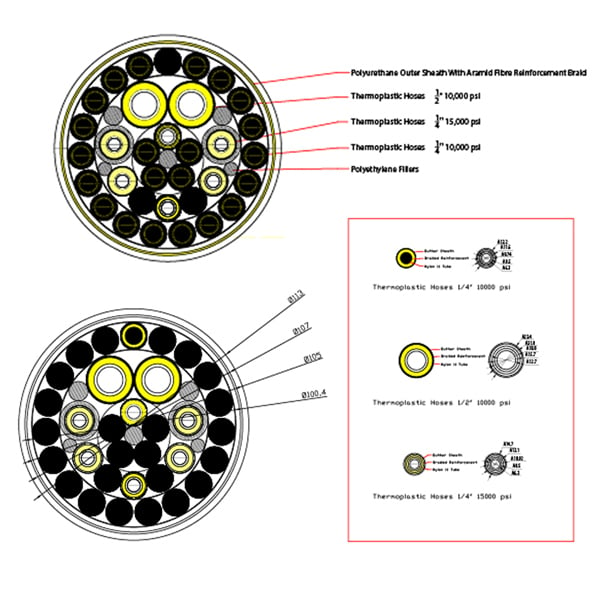

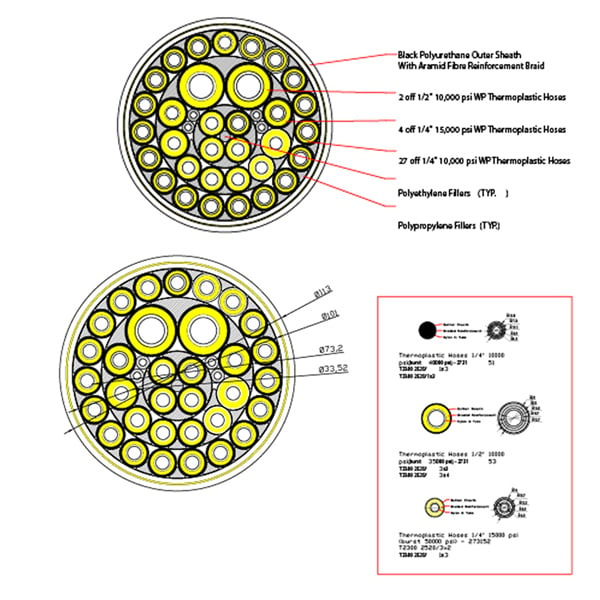

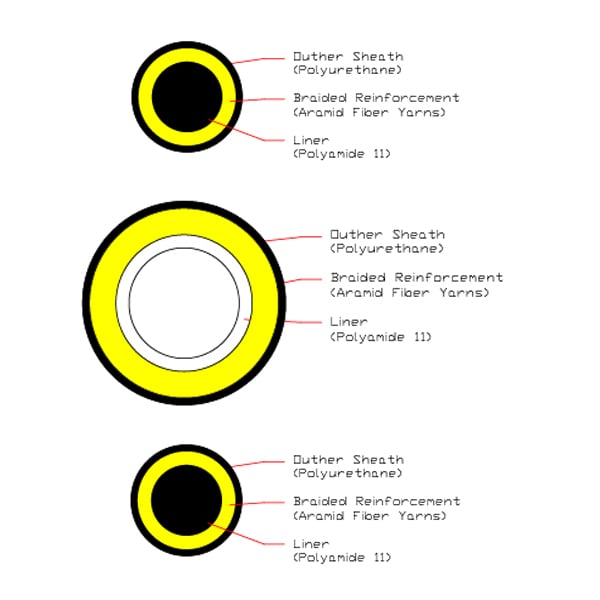

Thermoplastic Umbilicals are custom designed products made to provide Electro-Hydraulic connection between topside equipment to subsea equipment. TPU can assume several configurations used to transfer high and low pressure fluids supplies, chemical injection fluids, annulus fluids, and electrical power/signals. |

|

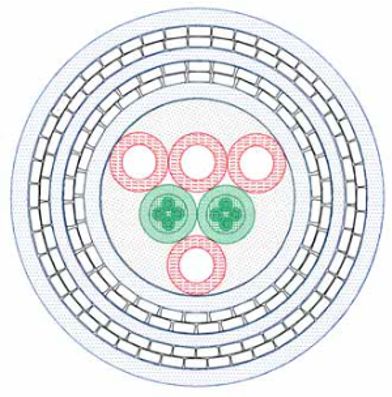

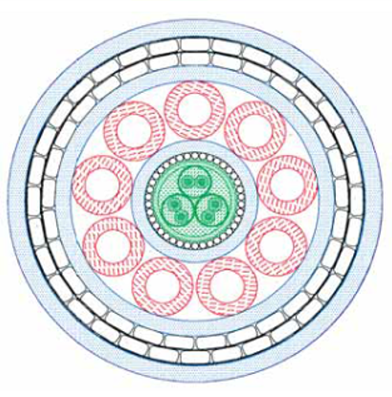

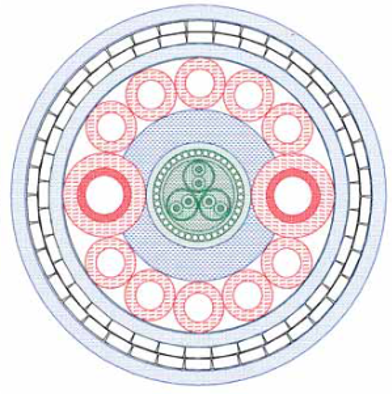

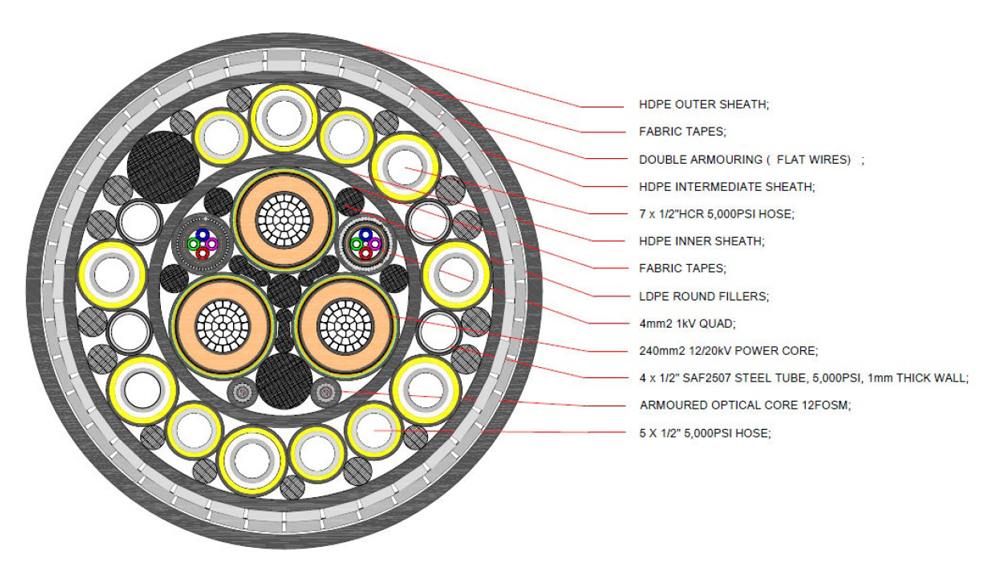

STU is an excellent solution for adverse conditions application. Metallurgical characteristics of duplex and super-duplex stainless steel tubes can offer mechanical resistance allied with highest corrosion protection against chemical compounds and offshore environment. Most commonly used to chemical injection and hydraulic control, STU technology provides enhanced response times and higher working pressures for hydraulic lines when compared to traditional thermoplastic hose based designs. STU solutions also eliminate the issue of chemicals fluids permeation through the lines when compared to traditional thermoplastic hoses. |

|

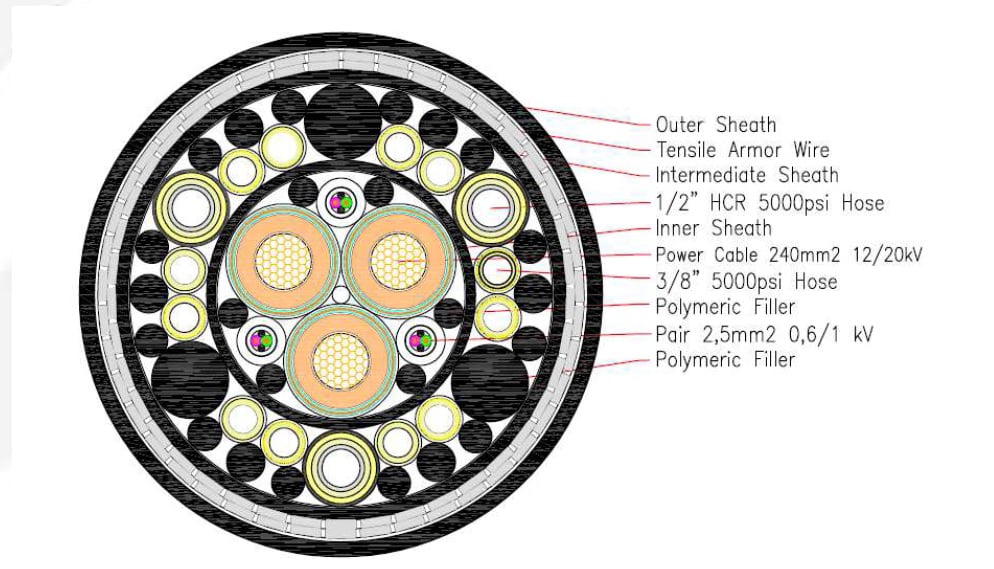

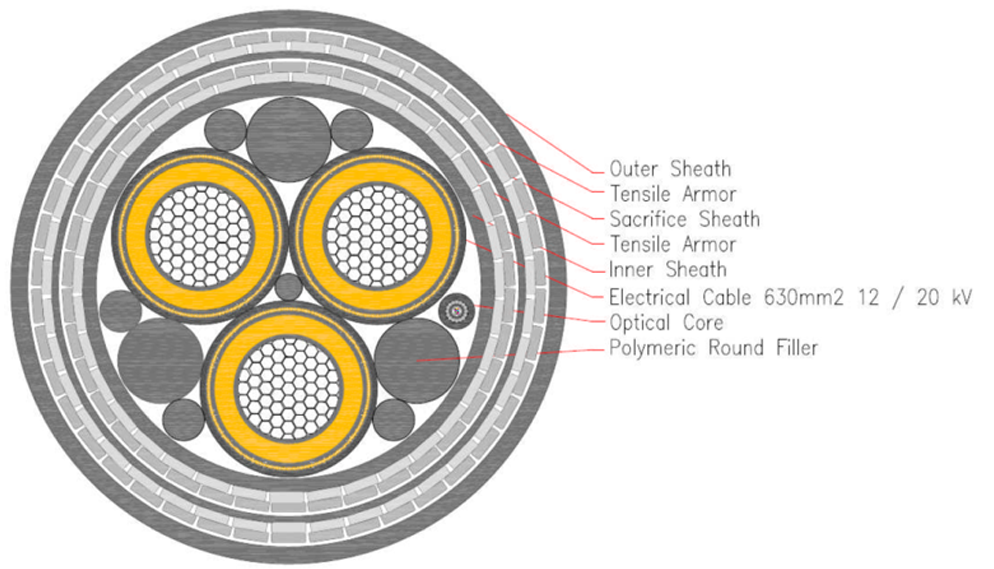

Individual steel tube umbilicals can contain a number of functional components with the cable. These can include: |

|

|

Umbilicals designed for power feed, control, distribution, monitoring and two-way communication between production units; also other functions: |

|

Umbilical Termination Assemblies (UTAs) are configured based on customer requirements and provide subsea connection solutions. The modular designs rely on a standard parts catalogue developed based on past project requirements and are equipped to meet the majority of customers' requirements. The standardization of parts fully supports configurability of the UTA to meet even the most challenging of installation and operational requirements. |

|

Flying leads are custom made solutions to link connections between subsea equipment. |

|

|

The Buoyancy Module consists of two main parts: the buoyancy element and the internal clamp. |

|

The Cobra Head consists of a structural frame, hinging stab, MQC plates, super-duplex tubing, and bulkhead style ROV electrical connectors. |