115

The Logistics function manages all the Group's intercompany

flows at the level of both annual budget and monthly opera-

tions, with the aim of satisfying demand in all markets that

do not have a local production source due to lack of capability

or production capacity. The Logistics function also manages

short and medium-term production allocations and planning

through Sales & Operations Planning (S&OP), a process

which serves as the link between the demand cycle (sales)

and the supply cycle (manufacturing and procurement). The

Group plans production according to whether a product is

classified as "engineer to order" (ETO), "assembly to order"

(ATO), "make to order" (MTO) or "make to stock" (MTS).

ETO: The ETO management model is mainly used in the

Energy Projects segment for Submarine, High Voltage and

Umbilical cables, businesses in which the Prysmian Group

supports its customers right from system design all the way

through to final cable laying.

ATO: The ATO approach allows a fast response to demand for

items that use standard components but differ only at the

final stages of production or packaging. This approach has

the dual objective of responding rapidly to market demand

while at the same time keeping inventories of finished goods

to a minimum.

MTO: Under the MTO approach, production is activated and

goods shipped only after receipt of a customer order, signifi-

cantly reducing unused inventory levels and the time that

raw materials and finished goods remain in stock.

MTS: In contrast, under the MTS approach, generally used for

more standardised products, inventory management focuses

on producing items for stock to allow a fast response to

demand. This model is mainly applied in the Energy Products

and Telecom operating segments.

In keeping with the Group's strategic objectives and as a

complement to the Customer Centricity and Factory Reli-

ability initiatives, Prysmian Group continued in 2014 with

the actions already undertaken in 2014 to improve logistics

services, in terms of lead-time flexibility, timeliness and

efficiency. New projects were also launched during the year

to strengthen the end-to-end processes with some Global

Key Accounts.

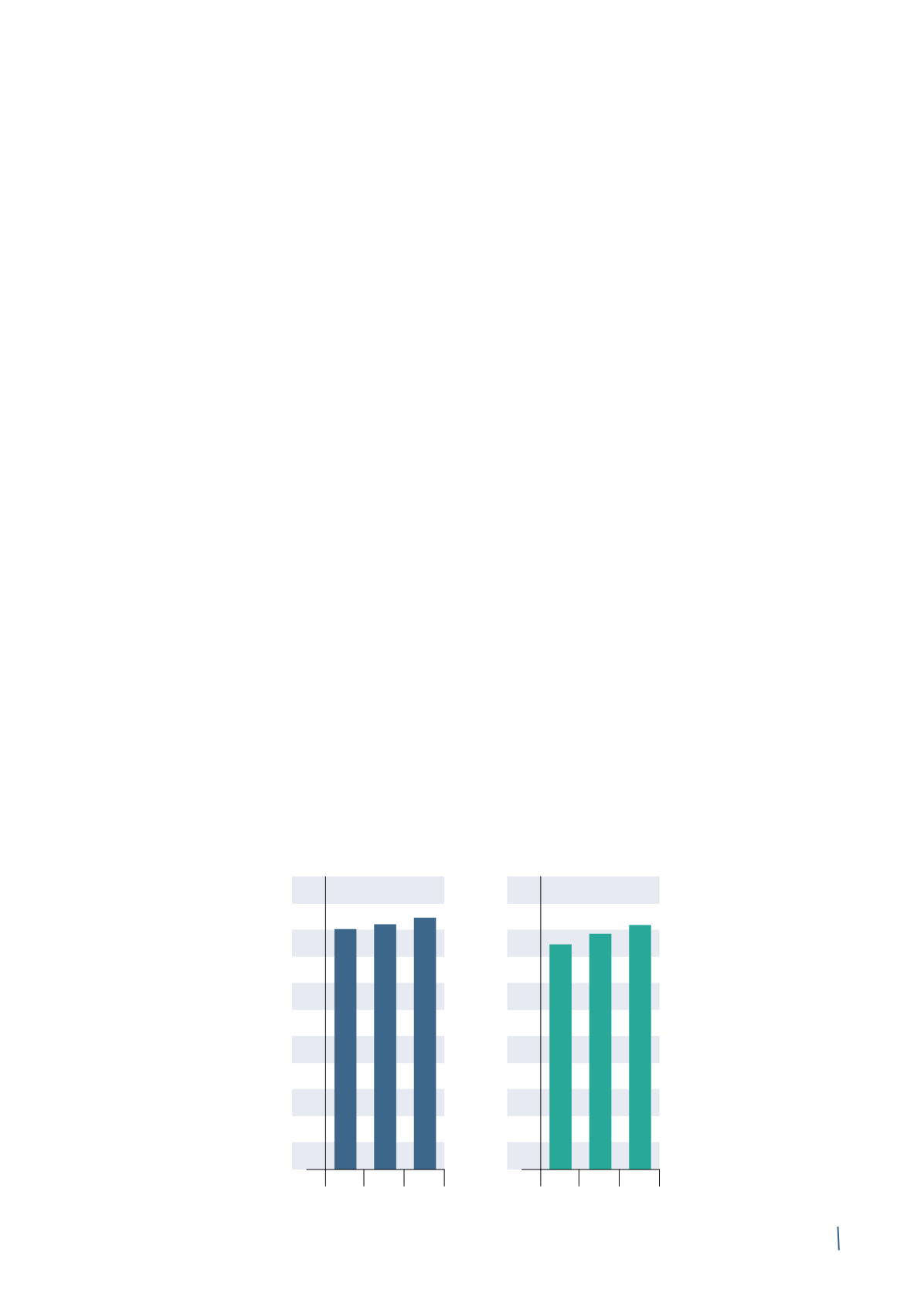

In terms of punctuality and reliability of its process, the

Prysmian Group confirmed its strong focus on continuous im-

provement. The On Time Delivery (OTD) statistics, measuring

the ability to serve the customer by the delivery date agreed

at the time of confirming order receipt, continued to improve

in 2014 in both the Energy Products and Telecom operating

segments, as shown in the following graphs.

LOGISTICS

In keeping with the Group's strategic objectives and as a complement to the Customer

Centricity and Factory Reliability initiatives, Prysmian Group continued in 2014 with the

actions already started in 2013 to improve logistics services, in terms of lead-time flexibility,

timeliness and efficiency.

ENERGY PRODUCTS

2012 2013 2014

100

90

80

70

60

50

40

30

20

10

0

90% 92% 94%

TELECOM

2012 2013 2014

100

90

80

70

60

50

40

30

20

10

0

85%

88%

91%

ON TIME DELIVERY

100

LOGISTICS