5.

EFFICIENCY CONTINUOUSLY INCREASING

PRYSMIAN GROUP

2015

YEARLY OVERVIEW

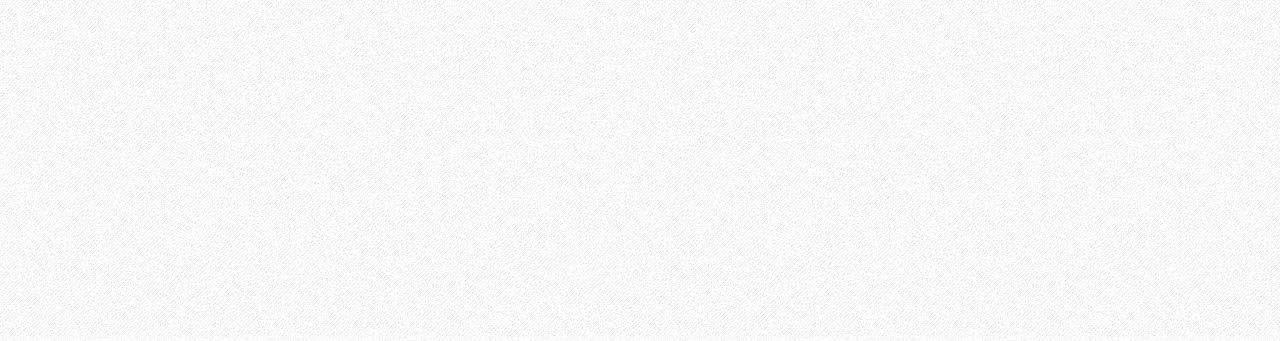

GLOBAL REACH, LOCAL EXCELLENCE

Prysmian Group’s manufacturing activities

are highly decentralised in 88 plants in 31

different countries. This is a strategic factor

enabling it to react quickly to different

market needs worldwide.

Once again in 2015 Prysmian pursued its

strategy of concentrating on higher value-

added, high-tech products in a limited

number of manufacturing facilities, which

thereby become centres of excellence

enabling economies of scale and reductions

in capital employed, and of making the

commodities area ever more efficient, with

a wide geographical presence to minimise

distribution costs.

Capital expenditure increased by 29% in

2015 to Euro 210 million, mainly reflecting

the significant resources invested in

manufacturing footprint projects, as well as

theusuallevelofinvestmentinthesubmarine

cables and optical fibre businesses.

About 44% of total expenditure was to

increase production capacity and change

the mix.

+29% increase in capex

"Factory reliability helped us improve quality,

customer service and efficiency yet again in

2015. Investments are focused on developing

centres of excellence throughout the supply

chain, with particular attention to improving

the environmental and social objectives".

Chief Operating Officer

Andrea Pirondini

Work continued in 2015 to boost efficiency to enhance the extensive production network around the world

but also to concentrate manufacturing activities for high value-added, high-tech products.