5.

EFFICIENCY CONTINUOUSLY INCREASING

PRYSMIAN GROUP

2015

YEARLY OVERVIEW

Implementation of the “factory reliability”

concept, introduced in 2010, enabled yet

more improvements in 2015 in the quality

of the planning and supply processes in

terms of controlling volumes and inventory

levels. Group suppliers source the main

raw materials used by Prysmian: copper,

aluminium,

lead,

various

petroleum

derivatives (such as PVC and polyethylene),

components for power and telecom cable

accessories, as well as special types of glass

and sheathing for optical fibre.

The strategic approach to supply chain

management is based on five priorities

that also include environmental and social

objectives.

A SUPPLY CHAIN DESIGNED FOR THE CUSTOMER

Metals, particularly copper and aluminium,

are a key resource for Prysmian’s production

processes: in fact, they account for around

70% of the raw materials used. Prysmian

purchases copper and aluminium wire rod

from the world’s leading manufacturers

and only in special cases does it produce

its own copper rod, the volume of which is

nonetheless less than 10% of the total.

Also in the case of aluminium, the Group

has decided to concentrate increasingly on

suppliers that are vertically integratedunder a

strategy that assures the security of supplies

while also having cost and environmental

benefits thanks to simplification of the

logistics and elimination of the ingot re-

smelting cycle.

The Group absorbs slightly more than 2% of

the world’s copper production and about 5%

of the copper used globally in the electrical

and electronic sector, representing one of

this market’s leading economic players.

The procurement strategy follows two

directions: firstly, procurement from

producers that are as integrated as possible

with the ability to guarantee long-term

supplies; secondly, procurement from all

major global producers, in order to ensure

efficient coverage of requirements and

optimise the metals logistics chain.

The Group has developed genuine

partnerships with the integrated suppliers,

while also entering into short-term

agreements with non-integrated suppliers

to assure the necessary flexibility.

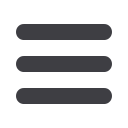

Total raw material purchases amounted to 1,155

ktonnes in 2015, of which 59% represented by

metals, consistent with the prior year figures.

Once again this year, 11% of the raw materials

used were sourced from recycled materials.

Metals, key resource to manage

Aluminium: simplification

of logistics

Copper: a major global player

RAW MATERIALS PURCHASED

BY THE GROUP IN 2015 (KTONNE)

Customer service continued to be

a focal point during 2015, under the policy

adopted in prior years with the objective

of improving flexibility, reliability

and time to market.

• ALWAYS AND ONLY USE QUALIFIED SUPPLIERS

• ONLY USE MATERIALS WITH APPROVED TECHNICAL

CHARACTERISTICS

• GUARANTEE CONTINUITY OF COMMODITY SUPPLY AND

AVAILABILITY OF REQUIRED VOLUMES

• GUARANTEE ON-TIME DELIVERY AND HIGH QUALITY

STANDARDS OVER TIME

• ENSURE COMPETITIVE PRICES

Chemical products

0.4%

Metals

58.4%

Ingredients

19.7%

Compounds

20%

Other (paper,

yarns, tape, oil)

1.5%