43

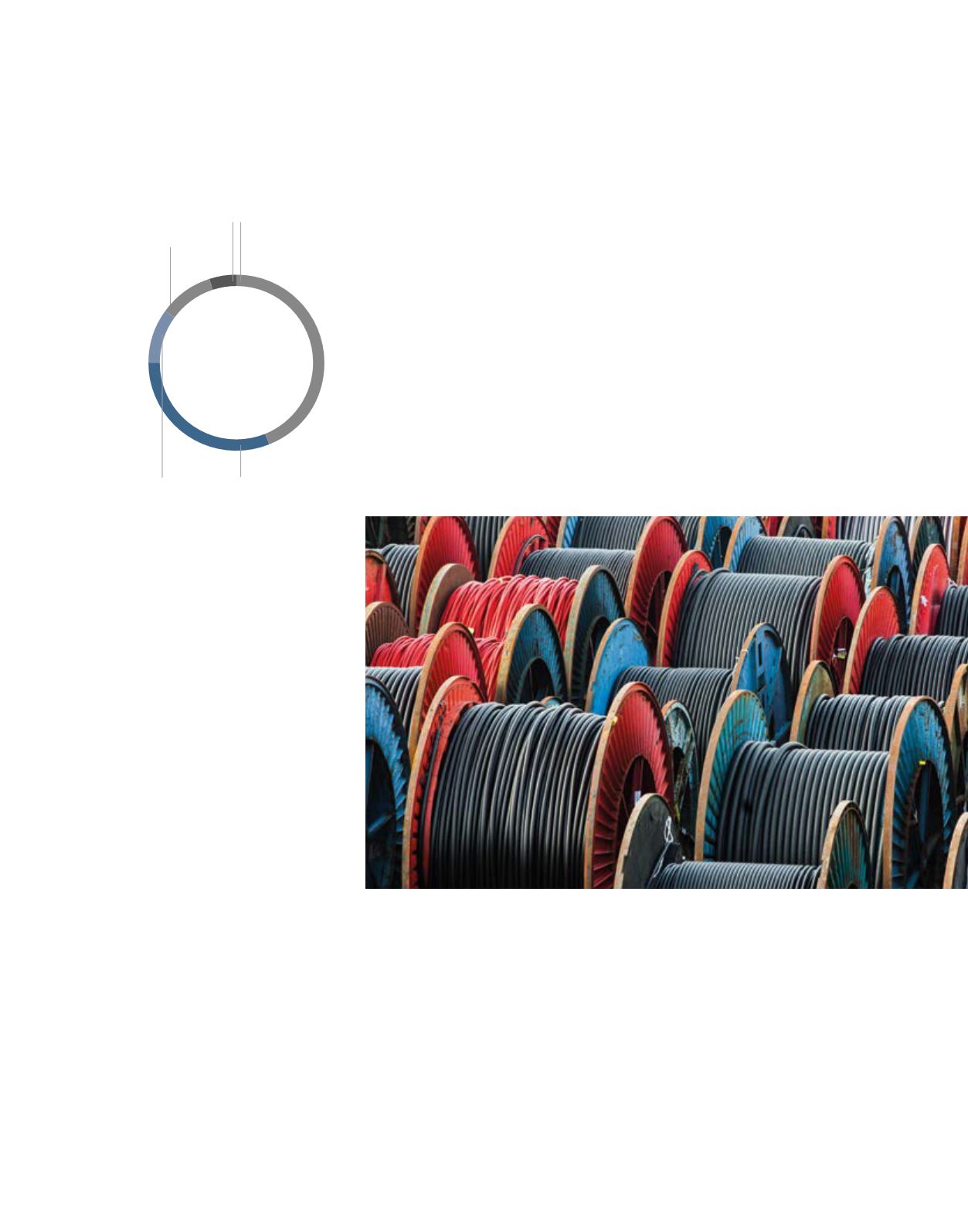

The Energy Projects segment saw significant

investments in the submarine cable plants

in Arco Felice (Italy) and Pikkala (Finland) to

increase capacity for the “50Hertz” contract;

this contract, worth more than Euro 700

million and awarded to the Group in 2014,

involves the design, supply and installation

of high voltage cable systems between

offshore wind farms in Germany.

Also in the submarine business, conversion

work started on the new cable-laying

ship known as “Pacifique”, a third vessel

dedicated to installation services which

will join the “Giulio Verne” and the “Cable

Enterprise” already in the fleet.

Capital expenditure in the Energy Products

segmentcontinuedtofocus,yetagainin2015,

on countries with the best growth potential:

• Suzhou and Tianjin, China: capacity

increased for Trade & Installer, Rolling

Stock and Elevator cables.

• Keila, Estonia: investments to create a

manufacturing hub for LV cables to serve

the North European market.

• Malaysia: new capacity created for

instrumentation and control cables for the

Far East market.

• Kistelek, Hungary: two projects being

completed to serve the Central European

market.

The High Voltage business saw completion

of two major investments initiated in 2014,

one at the Abbeville plant in the United

States for the construction of a second

vertical insulation line for Extra High Voltage

extruded cables, and the other at the Slatina

plant inRomania, to satisfy growing demand

in the markets of South-East Europe.

The Delft plant in the Netherlands was also

the subject of investment after winning a

High Voltage project fromTenneT, a German-

Dutch grid operator.

The Telecom segment continued working on

major projects to verticalise the optical fibre

production process at the Sorocaba plant in

Brazil and at Claremont in the United States,

forbetterservingtheNorthAmericanmarket.

There were also continued investments to

increase optical cable production capacity

at the factory in Slatina (Romania), where

work also started to build the new telecom

cables plant.

GROUP CAPITAL EXPENDITURE IN 2015

In submarine cables…

In fast growing countries ...

In high voltage…

… in optical fibre

The Group invested 31%of its total capex to achieve efficiencies and reduce costs, compared with 20%

in 2014. In particular, the Energy Products segment made significant investments in efficiency in the

metallurgical area, while the Telecom segment continued to invest in efficiency at its European optical

fibre manufacturing facilities in Battipaglia (Italy) and Douvrin (France).

In Tunisia, the Group decided to start expanding the Grombalia plant to bring in-house work previously

done by outside companies.

Ongoing drive for efficiency

Production capacity

increases/product

mix

44%

IT systems

and

R&D

5%

Other

10%

Efficiency

31%

Base-load

structural

maintenance

work

10%