71

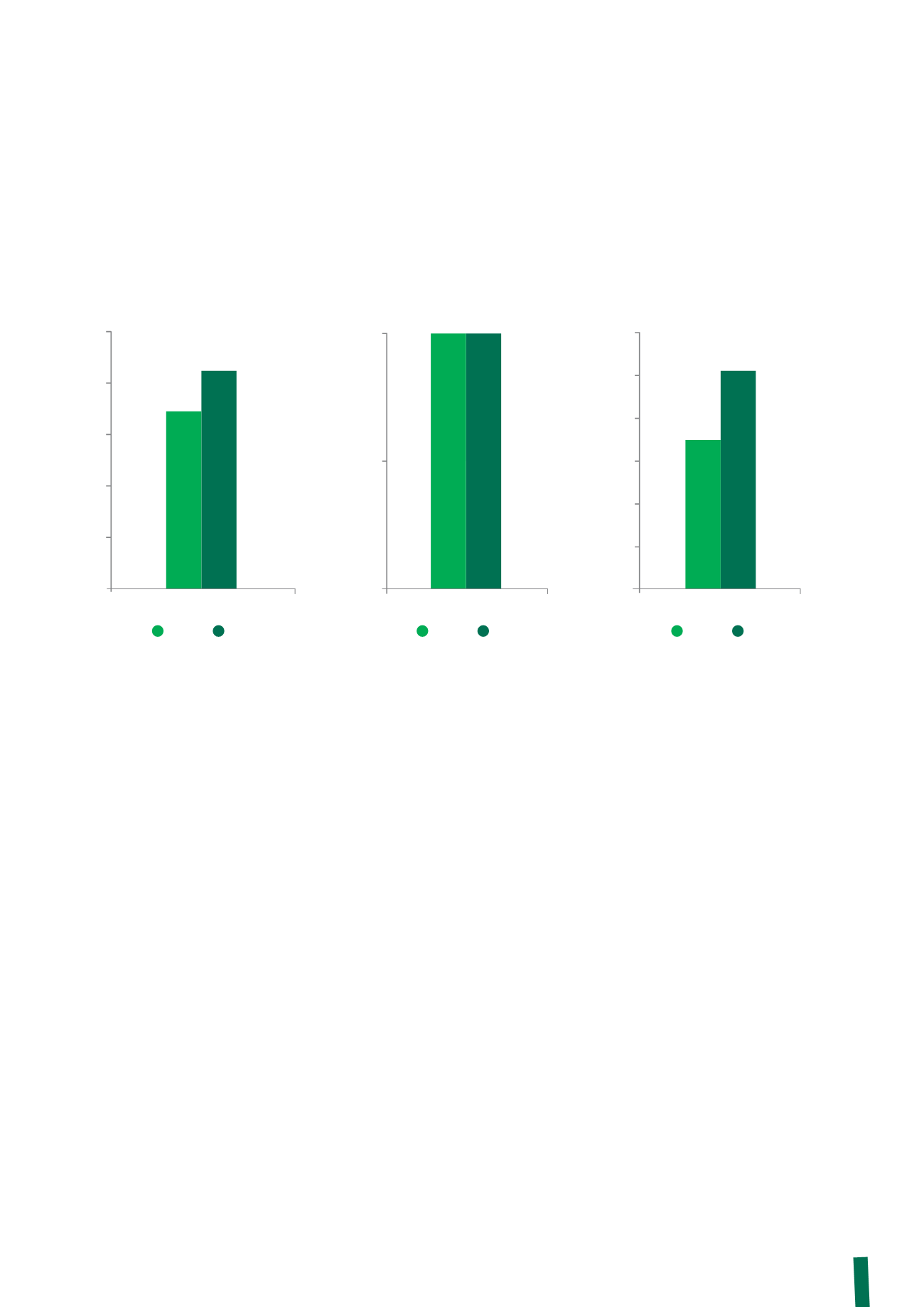

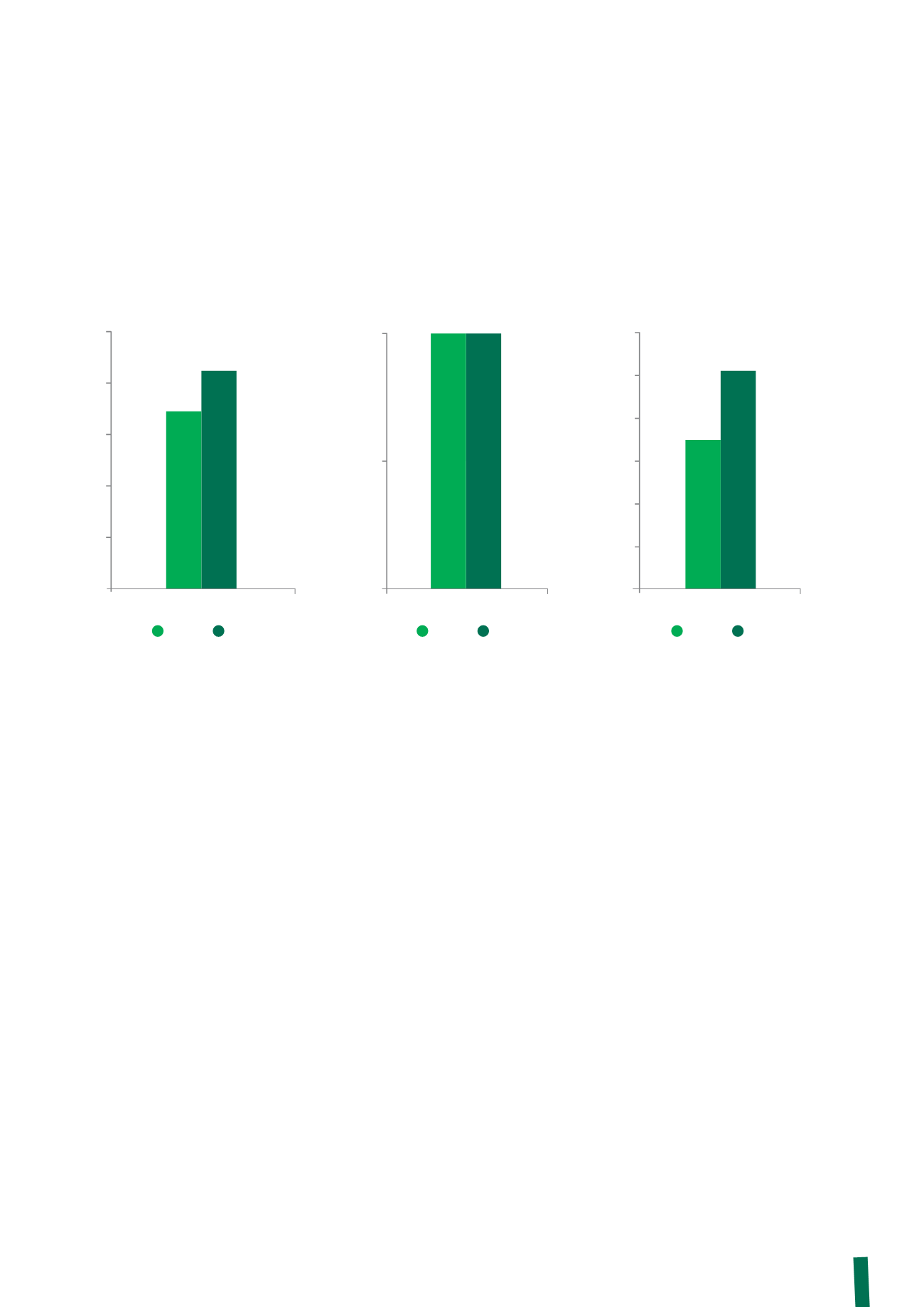

The production of hazardous waste per unit of production is detailed below for the following categories: energy cables, telecom

cables and optical fibre.

The hazardous waste produced by the power cables category

has increased slightly in absolute terms (+2%), but more

significantly per tonne of production (+13.5%).

The time interval for the cleaning of machines, which

generates waste emulsions and sludge, exceeds one year

in many cases, resulting in a slightly erratic flow of waste

disposal. In addition, it is necessary to consider:

• the different type of production resulting, in some cases,

in the use of a greater quantity of solvents and, in others,

in the need to clean the drawing lines in preparation for

processing a different material;

• the “one-off” elimination of equipment;

• greater use of the drawing lines, resulting in faster

consumption of the emulsions;

• the emptying of a fuel tank (which is not normally emptied);

• non-routine maintenance in order to repair sections of

processing lines, resulting in a spike in the generation of

hazardous waste at some factories.

In addition, production ceased at the Eschweiler and Fercable

(3) The unit of production data for 2012 and 2013 is not compatible for the optical fibre category, since the method of calculating total production has changed.

factories during 2013. In 2012, these locations had generated

a markedly lower than average quantity of hazardous waste

per unit of production, compared with the other factories that

produce power cables.

Lastly, significant improvements have been made at the

Vila Velha factory in Brazil, where the quantity of ethylene

glycol to be eliminated has been reduced by implementing an

appropriate system for the treatment of waste waters.

Telecom cables generated less hazardous waste, both in

absolute terms (-28%) and per km of production (-14%). This

was partially due to a lack of uniformity in the frequency

of eliminating this type of waste; indeed, the interval can

be years in many cases (many factories eliminated large

quantities in 2012). Other factors include the closure of

the Livorno Ferraris factory and fluctuations in the mix of

production, which generate different quantities of hazardous

waste.

The total amount of hazardous waste generated by the optical

fibre category during 2013 was 4% lower than in 2012.

5

4

3

2

1

0

4.09

Power Cables

Hazardous waste disposed

per tonne of product (kg/t)

3.60

2012

2013

0.02

0.00

0.010

0.02

0.02

Telecom Cables

Hazardous waste disposed

per kilometer of product (kg/t)

2012

2013

0.11

0.00

0.02

0.04

0.06

0.10

0.08

0.12

0.07

Hazardous waste disposed

per kilometer of product (kg/km)

3

2012

2013

Optical fibre