Leonardo da Vinci: the ‘genius’ is in motion

"Motion is the cause of all life" reported Leonardo da Vinci in the Codex Trivulzianus, and the state-of-the-art cable laying vessel that bears his name is ready to accomplish all the projects to which it is already committed. After over 1500 days of work and peaks of 900 people working on the project in a single day, from the keel laying at Vard’s shipyard in Tulcea, Romania to last outfitting phases in Brattvåg, Norway and sea trials activities, the cable layer was officially delivered and is ready to accompany Prysmian Group in its path as enabler of the energy transition towards a cleaner and smarter world.

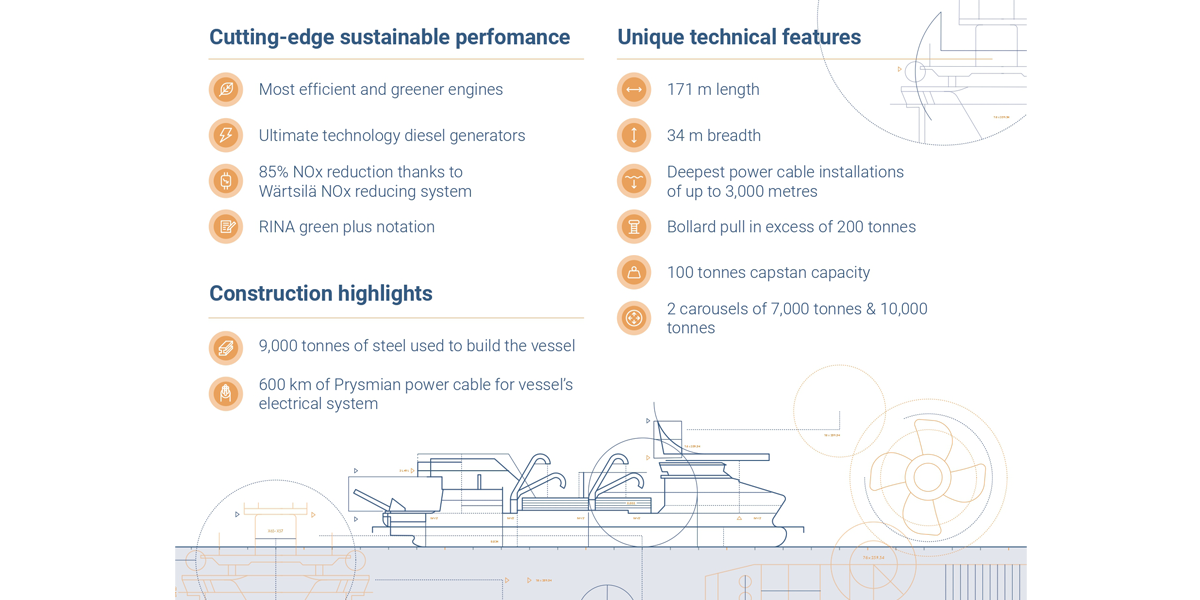

Prysmian Group used 9,000 tons of steel to build the Leonardo da Vinci and over 600 km of Prysmian power cable were needed to set up the vessel’s electrical system: the ship can now boast unique technical features and reach unprecedented performances, consolidating the Group’s leadership and boosting the capability of Prysmian Group submarine cable operations.

“This vessel represents a key strategic asset for our Group and, thanks to its versatility, will support us in several cable installation projects, strengthening our leadership in the interconnection and offshore wind farm markets”

Hakan Ozmen

EVP Project BU

“From the Viking Link, the world’s longest submarine power interconnection between the UK and Denmark, to the execution of other important projects such as the submarine power interconnection between the Spanish islands Lanzarote and Fuerteventura and the Saint Nazaire offshore wind farm in France, the vessel will play a strategic role right away. Europe is living a transition towards greener energy systems and we want to be at the forefront of this change”.

Hakan Ozmen

EVP Project BU

Unmatchable traits for the world’s most efficient vessel

Leonardo da Vinci is joining an already cutting-edge fleet composed of three vessels - Giulio Verne, Cable Enterprise and Ulisse – already in operation. The new cable laying vessel has unmatched features, such as 2 rotating platforms of 7,000 and 10,000 tons granting the highest carousel capacity in the market and ensuring overall projects efficiency. The vessel is design and equipped to carry out the deepest power cable installations of up to 3,000 metres also thanks to the new generation cable technology with synthetic armour which is 30% lighter than steel.

The vessel is equipped with state-of-the-art DP3 positioning and seakeeping systems. With a maximum speed above 16 knots, the vessel is also outfitted with two independent laying lines in order to increase operative flexibility and a bollard pull in excess of 200 tonnes giving the capability to perform complex installation operations supporting a variety of burial tools.

Sustainability at the core

The Leonardo da Vinci is powered by the most efficient and greener engines on the market: 6 Wärtsilä hybrid propulsion engines of which four are able to produce ≈4,500 KW each, while the other two ≈1, 440 KW each. In addition, Prysmian Group installed Class approved Wärtsilä NOx Reducer System that shrinks by 85% the emissions of nitrogen oxide, making the Leonardo da Vinci compliant with the latest IMO Tier III standard. Leonardo da Vinci, which can only be powered by Marine Diesel Fuel Oil with a sulphur content minor than 0.1%, is also designed with an embedded power regeneration system on cable laying equipment that recovers energy, and then send it back to the vessel's power grid.

The key to success

Along with avant-garde technologies and innovation, the success of this cutting-edge vessel lies also in the people who took part in it.

“I’m very glad that the Leonardo da Vinci is finally ready, and I am really proud of the work that has been done by the team involved from 2019 until the very end. This achievement was made possible by the hard teamwork performed by Prysmian employees, Shipbuilding Company personnel, Subcontractors and in general all the people involved who committed themselves to this project”

Dario Brivio

Prysmian’s Project Manager on Leonardo da Vinci