Prysmian strengthens power grid with strategic connections in Bahrain

The Kingdom of Bahrain, an island country between Saudi Arabia and Qatar, has a great need for interconnections to support growing energy demand. With this in mind, ‘Base’ and ‘Loop’ projects were initiated, which are crucial to country’s new 400 kV backbone network and support economical, reliable grid expansion. Prysmian is providing turnkey management and realisation of parts of both projects.

Recently, Prysmian successfully handed over the Base Project to the client, the Electricity and Water Authority of the Government of the Kingdom of Bahrain (EWA). This strategic 400 kV transmission program was launched to improve EWA’s electrical grid and strengthen supply to the city of Manama. “The reason for implementing a 400 kV transmission line is closely related to the country’s industrial development and population growth, resulting in vastly increased energy demand in recent years,” explains Gianluca Barbato, Project Director - Prysmian Group. “The Base Project aims to realise Bahrain’s long-term plan to secure electricity resources that support sustainable economic growth, in line with the Bahrain Economic Vision 2030.” Bahrain’s current grid mainly incorporates systems running at 66 kV and 220 kV. The 400 kV Transmission Development program aims to ensure support and complete integration with the 220 kV system.

Prysmian has been awarded this 50 million order in 2015 for the engineering, production, civil works and installation of one circuit of the HV underground cable transmission that links the S/S HIDD, S/S Umm Al Hassam and Riffa S/S substations. 65 km of 400 kV XLPE insulated Extra High Voltage underground cables, for installation in Manama city, were produced at Prysmian’s centre of excellence in Gron, France.

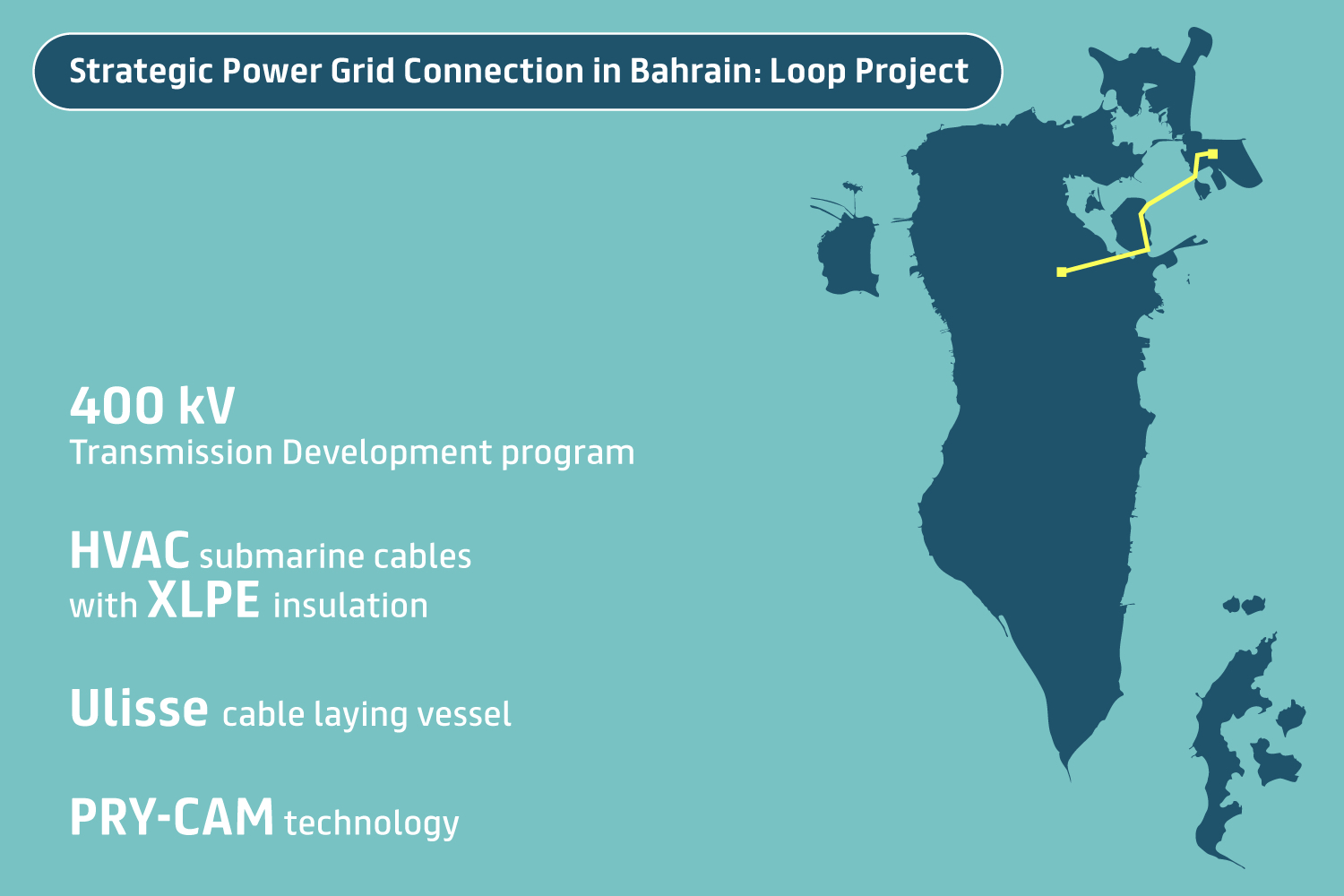

EWA’s strategic 400 kV Transmission Development program requires an additional 400 kV cable loop circuit. EWA awarded Prysmian Group another contract, worth of €80 million, to develop the Loop Project in 2017. It adds a crucial link to the Kingdom’s infrastructure and is the first 400 kV submarine cable with XLPE insulation to be installed in the GCC (Gulf Cooperation Council) Region. Completion is expected to take place in summer 2020. “The Loop Project will be the first ever submarine connection installed in Bahrain,” adds Gianluca. “It will enhance the country’s transmission capability and support integration within the GCC interconnection grids that link Bahrain to Saudi Arabia, Kuwait and Qatar. In this way, the project will mitigate high short-circuit problems and address possible issues related to system reliability and maintenance.”

Prysmian took care of design, supply, installation and commissioning of the 400 kV HVAC link, measuring nearly 13 km. In addition, the Group is supplying three 400 kV HVAC land cables with XLPE insulation for some 46 km. The submarine cables are made at Prysmian’s state-of–the-art plant in Pikkala, Finland. Land cables are produced in the centre of excellence in Gron, France.

Prysmian also supplied an integrated monitoring system for Partial Discharge (PD) and operating temperatures based on the Group’s innovative PRY-CAM technology

PRY-CAM is a breakthrough technology paired with a suite of electronics-based products that allow performing online measurement and data gathering and analysis of key parameters without service interruption, resulting in effective prevention of failures and associated costs, and increased reliability of electrical systems as well as enhanced safety for operators.

Gianluca added: “Integrating PRY-CAM monitoring solutions on the entire cable system gave the customer a robust and data-driven new way to assess and monitor asset conditions, resulting in a significant improvement of the asset maintenance and management strategy. Cables for both projects were mainly installed in Manama. This city features a significant presence of intrinsically interrelated primary urban infrastructures, for electricity, water, communication network, drainage, sewerage, oil and gas, and more. This interfered with the implementation of our 400 kV cable installation, so an extensive effort was orchestrated to carefully manage involved stakeholders, and a dedicated local team was created.”

The Group used its own cable laying vessel Ulisse for submarine cable installation operations of the Loop Project. Target burial depth along the route was revised and increased up to five meters, in order to reduce any risks of future damage and with the vast amount of marine traffic in the installation corridor in mind. Based on experience in North European projects, the Vertical Injector tool is utilised to perform burial operations. This high-tech burial tool is capable of deep trenching, using water jet arrays to cut trenches up to 10 metres deep.

Prysmian presence in Middle East

Prysmian has received a contract for another strategic project in Middle East combining a wide range of technologies: the Hidd-Shamal Al Fateh 220 kV cable connection. The Group’s presence in Bahrain dates back to 2006, when Prysmian was awarded a contract by the GCC Interconnection Authority (GCCIA) for a 400 kV oil-filled cable submarine interconnection between Saudi Arabia and Bahrain. Other projects further demonstrate Prysmian’s commitment to developing energy infrastructures in the Gulf area, including the 400 kV power transmission system for the Phase XI underground cable system (Qatar) and the MEW 06 Jaber Al Ahmed City and Jamal Abdel Nasser Street projects (Kuwait).