Arco Felice, the record-setting factory where all cables are custom made

This idyllic seaside location and the fact that the factory is surrounded by a town creates specific environmental challenges, explains Health Safety and Environment Manager Paola Visingardi.

“Our only wastewater is rain water, and it is 100% treated before it goes into the sea,” she explains. “We check our water quality every three months and are always well below the AIA limit” of pollution standards.

Simona Squarzoni was among the first blue collar women to be hired, in 1999. She was also the first woman to successfully become certified as a cable jointer, a demanding artisanal job requiring a high level of technical skill. She now works on the Lead & Polyethylene machine.

“I always want to try something new,” she says. “Now I would like to learn to drive a forklift.”

This idyllic seaside location and the fact that the factory is surrounded by a town creates specific environmental challenges, explains Health Safety and Environment Manager Paola Visingardi.

“Our only wastewater is rain water, and it is 100% treated before it goes into the sea,” she explains. “We check our water quality every three months and are always well below the AIA limit” of pollution standards.

Simona Squarzoni was among the first blue collar women to be hired, in 1999. She was also the first woman to successfully become certified as a cable jointer, a demanding artisanal job requiring a high level of technical skill. She now works on the Lead & Polyethylene machine.

“I always want to try something new,” she says. “Now I would like to learn to drive a forklift.”

Enabling market leadership through manufacturing excellence

For example, in June the factory had to produce Prysmian’s first-ever non-metallic armoured cable for installation in the Cyclades Islands in Greece. This cable is designed to be 30% lighter than steel-wrapped equivalents, so Prysmian’s four ships can load more of it, and will enable Prysmian to set new depth records for installation. To make it, Salvatore Bernardo’s maintenance team had to transform the 8,000-ton storage platforms so that they could hold a larger volume of cable.

“Just like our cables are prototypes, the machines are unique too,” says Bernardo.

Prysmian’s leadership in submarine cables and record-setting installation depths would not be possible without the manufacturing excellence at Arco Felice. The plant is now gearing up for another record-setting order: Viking Link. Worth close to €700 million, this England-Denmark link will be the world’s longest subsea cable at 1,250 kms, loaded directly from the plant’s pier to be installed by Prysmian’s new state of the art Leonardo da Vinci cable laying vessel.

“The Viking project will last three years, and will help us further improve the plant,” says Production Manager Mario Gallo. “We may make new investments.”

Project numbers:

500 employees

Total staff

50 women

Female employees

20

Production lines

1,250 kms

Length of Viking Link cable

This idyllic seaside location and the fact that the factory is surrounded by a town creates specific environmental challenges, explains Health Safety and Environment Manager Paola Visingardi.

“Our only wastewater is rain water, and it is 100% treated before it goes into the sea,” she explains. “We check our water quality every three months and are always well below the AIA limit” of pollution standards.

Simona Squarzoni was among the first blue collar women to be hired, in 1999. She was also the first woman to successfully become certified as a cable jointer, a demanding artisanal job requiring a high level of technical skill. She now works on the Lead & Polyethylene machine.

“I always want to try something new,” she says. “Now I would like to learn to drive a forklift.”

A unique factory with unique challenges

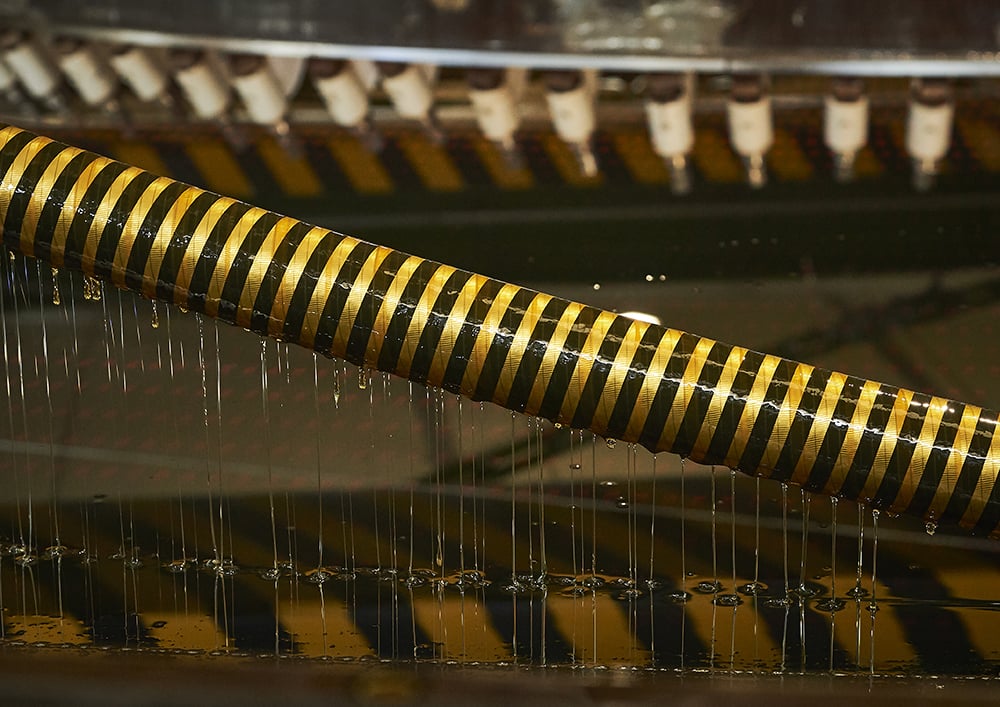

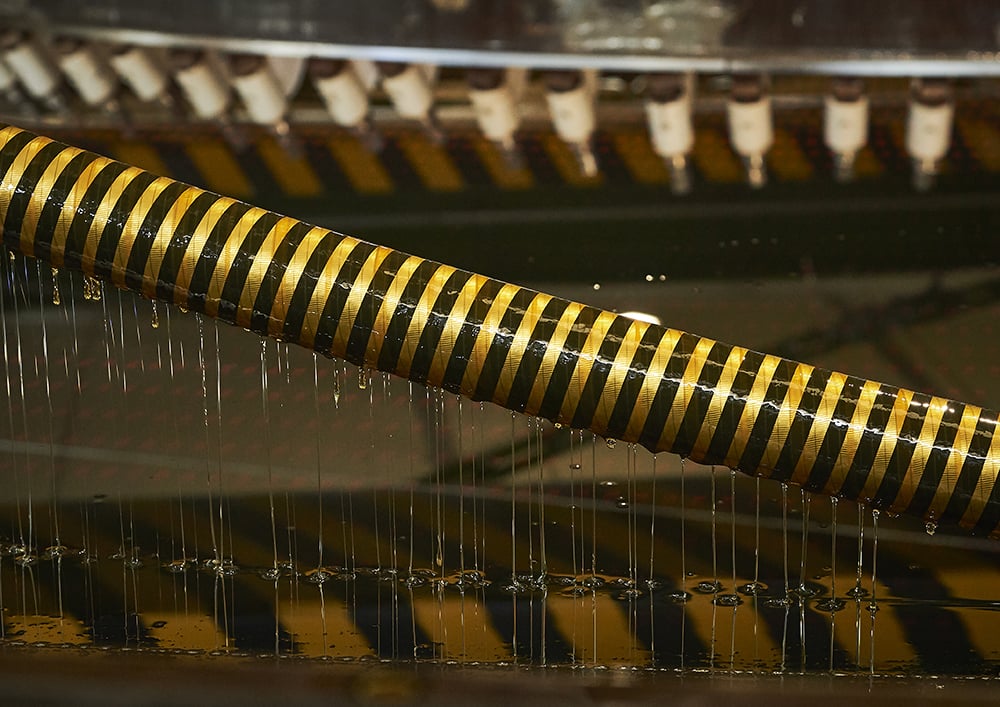

Arco Felice is one of Prysmian’s four plants that make submarine cables, but it is unique. For starters, it is the group’s only plant that makes paper-wrapped underwater cables.

Then, there’s the view. Located on the seaside town of Pozzuoli south of Naples, the plant’s offices look out over the water to the island of Capri (on a clear day). Across the bay of Pozzuoli is the Castello di Baia castle, built by the Crown of Aragon in 1495. Visitors entering the office lobby pass by a piece of a doorway from an ancient Roman villa found five meters below the site. The factory has close links with Pozzuoli, where Academy Award-winning actress Sofia Loren grew up. Many of the employees come from the town or the surrounding area.

This idyllic seaside location and the fact that the factory is surrounded by a town creates specific environmental challenges, explains Health Safety and Environment Manager Paola Visingardi.

“Our only wastewater is rain water, and it is 100% treated before it goes into the sea,” she explains. “We check our water quality every three months and are always well below the AIA limit” of pollution standards.

Simona Squarzoni was among the first blue collar women to be hired, in 1999. She was also the first woman to successfully become certified as a cable jointer, a demanding artisanal job requiring a high level of technical skill. She now works on the Lead & Polyethylene machine.

“I always want to try something new,” she says. “Now I would like to learn to drive a forklift.”