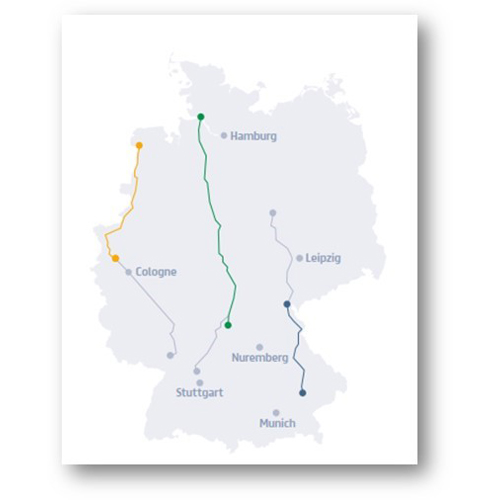

German HVDC cable projects: Prysmian at the core of the European energy transition

SuedLink, SuedOstLink and A-Nord are three state-of-the-art underground HVDC cable links running for hundreds of kilometers across Germany, linking the northern coasts where the wind power is captured by the offshore wind farms to the southern heartland where the clean electricity is needed by households and industry. Prysmian has been chosen by transmission system operators to design, manufacture, transport, store, install, commission, test and put into operation these high-tech cable systems in what is one of Europe’s largest energy infrastructure projects.