Interview with Dario Brivio

Describe the design and construction process of a cable-laying vessel like Leonardo da Vinci.

From a project management point of view, the Leonardo da Vinci project is a real challenge - Building cable-laying vessel is not Prysmian Group’s core business. The process, that started in 2017 with the design and engineering phase and calls for tender for subcontractors, can be divided into five fundamental stages. Stage 1 is the basic design, which takes up to a year and includes both the naval architecture of the vessel and the cable-laying equipment to be installed. Stage 2 is the hull construction, which has to meet stringent requirements to meet the various quality and classification standards. Stage 3 is the launch of the bare hull, which will then be towed to the Vard facility in Brattvag, Norway. Stage 4 is the outfitting and commissioning; the vessel is based on a naval platform by Vard, but Prysmian Group is responsible for the cable-laying equipment and all the systems will be thoroughly tested first on dry land. The last stage 5 is the rigorous sea trial that will take place in the North Sea before final delivery.

At what stage of construction is the project currently?

Cutting of the steel plates got under way in the spring, followed by the keel laying ceremony in September. The heavy welding work is currently in full swing at the Vard shipyard in Tulcea, Romania, where the blocks are being assembled and the hull is well in progress approaching the planned completion. I’m happy to say that the project is progressing on schedule and by the end of February next year we will start installing the engines prior to the launch and the transfer to Norway.

What are the unique characteristics of a cable-laying vessel in terms of design and naval architecture?

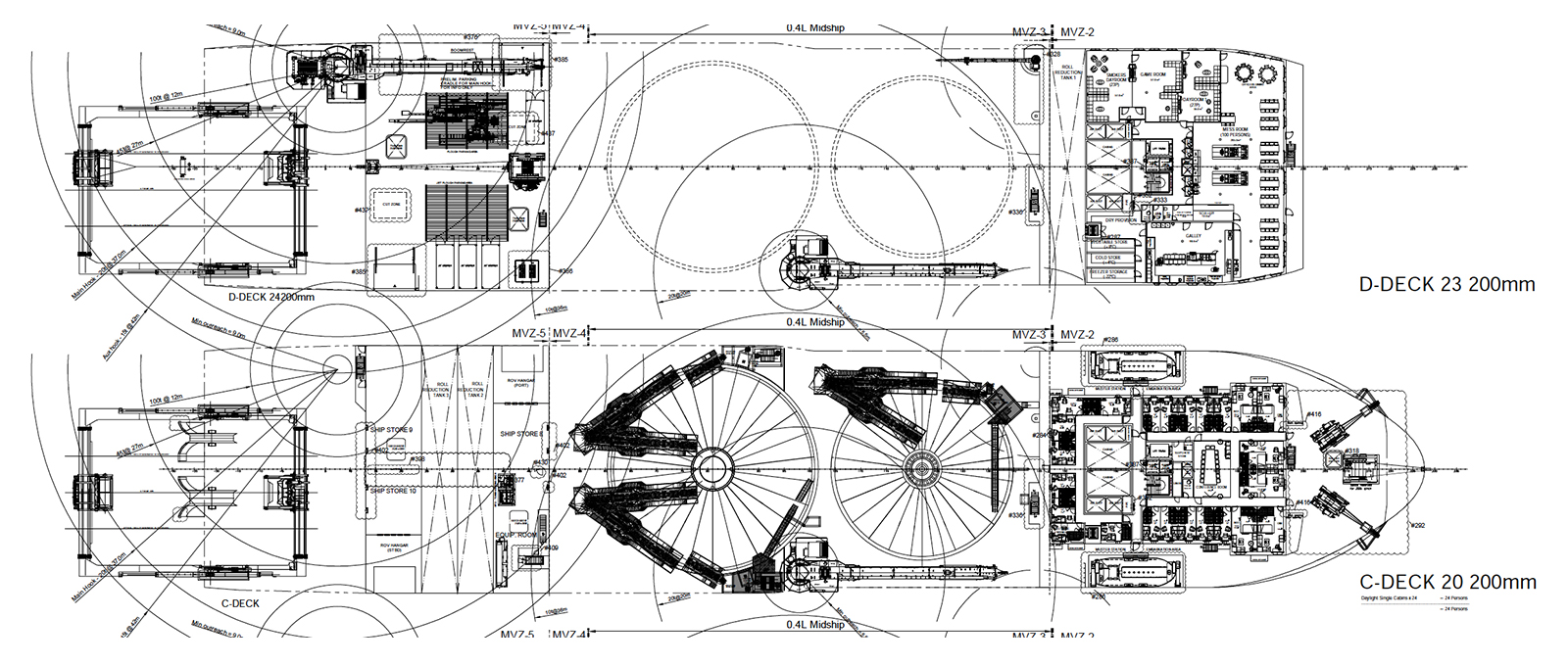

Cable-laying vessels are highly specialised ships required to operate independently far from shore, often for weeks at a time and in severe weather. It follows they have to be extremely robust and autonomous. In fact, Leonardo da Vinci will have an autonomy of 90 days and be able to operate in very harsh conditions. As the cables are laid strategically at immense depths, they must also be very manoeuvrable, so they are fitted with azimuthing thrusters that can swivel 360 degrees. These are controlled by Dynamic Positioning and Dynamix Tracking systems to pinpoint the exact location of the ship in mid-ocean and lay the underwater cables appropriately. Because of the many kilometres of cable they’re required to carry, these ships need huge deck space for storage. Leonardo da Vinci, for example, will have two carousels with a capacity of 10,000 tons and 7,000 tons respectively.

In what ways is the Leonardo da Vinci ground-breaking compared with other cable-laying vessels?

The tremendous development in the field of submarine cables, as well as the diverse nature of individual cable-laying operations, has meant there is a growing need for vessels with special characteristics that can be used exclusively for cable-laying. In the past, such vessels have often been converted from other types of ship already available on the market and fitted for the offshore business. Leonardo da Vinci, Prysmian’s fourth cable-laying vessel, is specifically designed and engineered from scratch for the sole purpose of laying submarine cables in the most efficient way, even in extreme environments. Equipped with last-generation machinery and technology, as well as a hybrid propulsion system with battery banks for energy storage and peak shaving, when the vessel is operational it will be able to carry more cable and operate more efficiently at greater depths than any other vessel in the field.