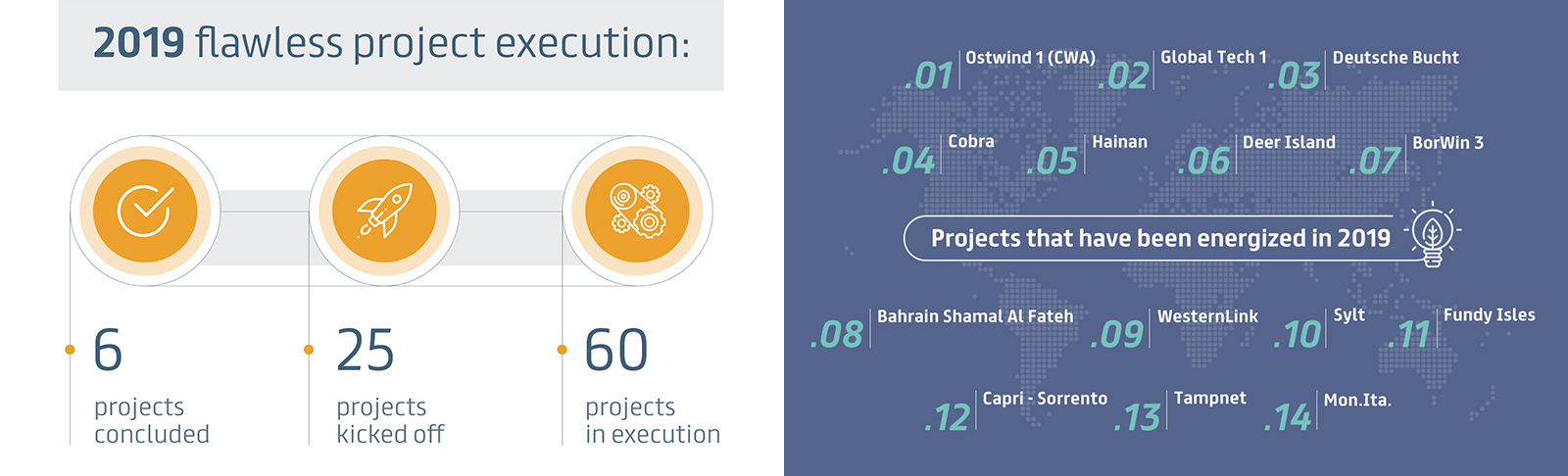

Projects BU is building on historical know-how to achieve flawless execution

Gaining flexibility to look for new ways of improving our activities and operation

“In the past five years, we have been able to build on the historical knowhow of the Group by adding a new set of skills and competencies to complete our go-to-market model”

Alberto Boffelli

Chief Operating Officer

By investing in new capabilities, the Group gains flexibility to look for new and better ways to deliver results. Prysmian invested about €50 million in new capabilities in 2019 and plans to invest another €50 million this year. Prysmian’s solution to deliver EPCI projects is the result of the contribution and collaboration daily between people involved in project management and execution: a strong procedural and cultural change improving project execution. For example, all 50 project managers will be certified by the Project Management Institute (PMI) and will use ISO 21500 guidelines as best practice reference for project execution.

In addition, health and safety procedures - already in line with international standards - are being extended from the factories and vessels to the entire supply chain of subcontractors. Prysmian’s strong commitment was demonstrated also during the first Projects BU HSE event held in November 2019. With the slogan “Working Safely Is the Only Option” targeted at more than 100 participants, including suppliers and key customers, Prysmian demonstrated how HSE requirements are vital for itself and its partners, establishing the leading role of the safety culture with regard to project execution.

“We organised this event with the purpose of reinforcing HSE commitment and sharing Prysmian Projects BU’s vision and expectations, considering suppliers’ contribution crucial to achieving this goal and to strengthening our safety culture with regard to project execution"

Hakan Ozmen

EVP Projects BU

Aligning the organization to reach news goals through change management was the second. “We have invested a consistent amount of time into change management in the company over the past years, and this has resulted in a very good level of understanding of what the industry wants,” Alberto says.

In addition, shifting project planning from a purely industrial goal of saturating physical assets to a goal of reliable project execution was key, because it has improved the unit’s ability to plan. And planning, of course, is the key to risk management, which is the last key point.

“Over the past years, we have moved from being brilliant in problem solving to being good in risk assessing and risk avoidance,” says Alberto. “Our customers have to see us as the most reliable and innovative partner in the market that offers a new solution delivered in a predictable way to enhance the value and the reliability of their assets.”