Manufacturing at Prysmian: getting it “right first time”

Process Engineering Manager Giovanni Ruggiero explains attacking waste at Italy’s FOS optical fibres plant

Process Engineering Manager Giovanni Ruggiero explains attacking waste at Italy’s FOS optical fibres plant

Everyone hates waste. But unlike most people, Giovanni Ruggiero, responsible for Draw Optical Fibres Process at Prysmian Group’s FOS plant, hunts down and squeezes out waste every day as part of his job.

“Our goal is to guarantee and make the production process the most efficient as possible, with the least cost possible,”

he explains.

“So, that means reducing waste maintaining a high OEE level.”

A more efficient process with less waste means higher margins, indeed any increase in waste impacts directly on fibre costs. FOS, or Fibre Ottiche Sud, produces about 50% of all the optical fibre made in Europe by Prysmian Group, and Prysmian is Europe’s largest producer of optical fibre. Even at a high-tech factory like FOS, the waste can be traced to four main areas. The causes can be always identified in the 4M “men, machines, method, or material,” says Giovanni.

In other words, human error, a machine glitch, a faulty operating procedure, or inadequate raw materials. In each case, the root cause and the solution is different. It’s not permissible for something to “go wrong”, production output has to be “right first time.” The goal is to get it “right first time,” because every time it doesn’t happen the cost goes straight to the factory’s bottom line. This is also part of the aim of the Six Sigma training that Giovanni and others receive through participating in the Make It program. He puts it to use every day in his work.

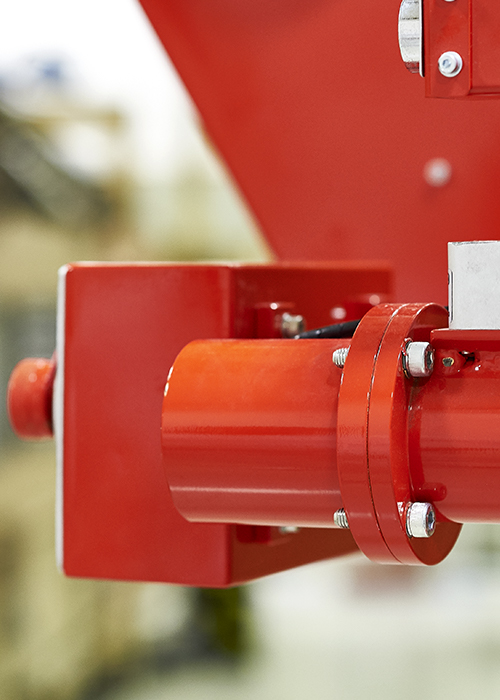

The factory’s entire staff has one main focus: making sure the optical fibres production process is as efficient as possible by reducing waste, both of raw materials and of human labour.

Giovanni Ruggiero, a Naples native, joined Prysmian in 2017 through the Make It program and landed at FOS. He has a masters’ degree in Mechanical Engineering from the University of Naples. Giovanni pointed to two projects that cut waste as examples of how it can work.

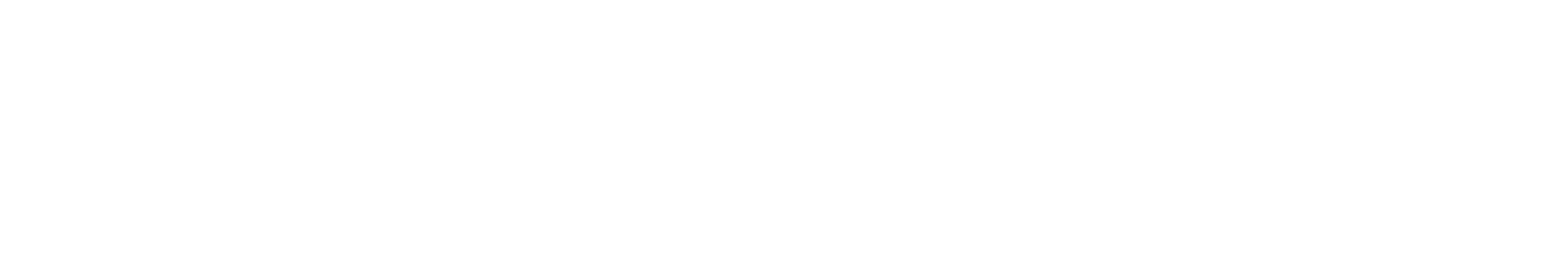

In the first one, he and his group attacked the 4M all at once to achieve a better deposition yield – simply a way of measuring waste during the process whereby silica is deposited producing “glass preforms” used to make the final fibre that are used for cables. Giovanni and the team set up a technical task force setting a matrix for each problem, laying out a series of projects with owners and timings for all of the “Ms”. As a result, they improved the deposition yield overcoming initial targets.

Then he moved on fibres and also here the scraps were reduced using a Six Sigma approach.

“Now we are better than the management plan,”

he says.

“This has a big effect on costs and on Clients, always very sensitive to the quality“

“The key to success was a strong collaboration among technology, process engineering, maintenance and production,”

he said.

This commitment to continual improvement is driven by people, not only machines. It must come from the dedication of the 250 operators and 50 employees who work at FOS, from the engineers and technicians on the factory floor to researchers and managers. Giovanni works closely with his staff of six process technicians, to keep them motivated. He says he enjoys this part of his job because he likes to work with people.

“A large part of my job is to motivate the team, inspire them, and to obtain the right credibility to propose our solutions,”

he says.

“That’s the main part. All of the rest comes easier as a consequence.”