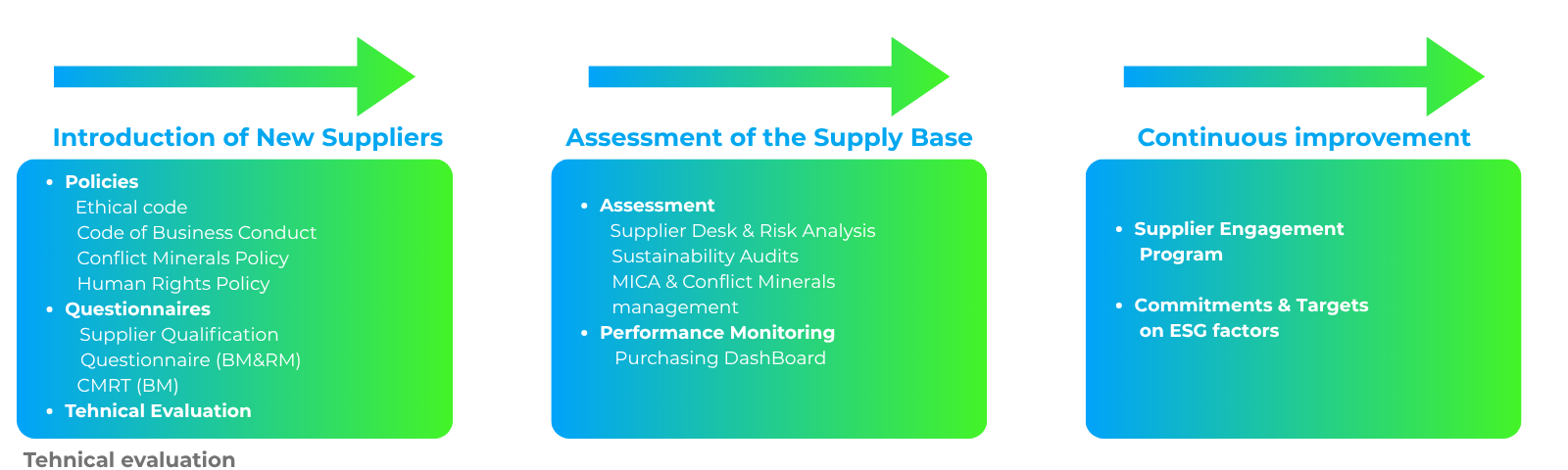

The Group continuously strengthens its relationships with strategic suppliers of the main raw materials used to manufacture cables, seeking to build with them an organizational process marked by sustainability throughout the entire production chain. In 2024, we continued to define a set of environmental and social strategies for the supply chain that take ESG factors into consideration. We carefully analyze risks relating to suppliers and raw materials and apply ethical policies and standards to issues such as Human Rights and "Conflict Minerals", and also adopt a Code of Responsible Business Conduct.

To further support our goals, we have included ESG KPIs in our supply chain assessment and activated a new Vendor Management Portal for the improved monitoring of ESG principles.